The backpack industry is a diverse and rapidly evolving field where the choice of material plays a critical role in the quality and consumer experience of the product.

Backpacks, as indispensable accessories in daily life and outdoor activities, rely heavily on fabric choices that dictate the long-term durability, functionality, and comfort of the product. The distinct characteristics of different fabrics make them more suitable for specific types of backpacks—from daily commuting backpacks to specialized outdoor packs.

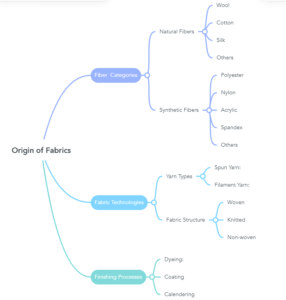

Origin of Fabrics

Fiber Categories

Fibers are classified as natural or synthetic.

Natural Fibers include Cotton、Wool、Silk et al. Cotton is Soft, breathable, but less durable; Wool is Insulating, moisture-wicking, but can be itchy or expensive; Silk has a Luxurious feel, lightweight, but fragile and expensive. Wool and silk are more often used for clothing.

Synthetic fabrics are just too much, the main ones are Polyester, Nylon, Acrylic, Spandex, and so on. Polyester is Cost-effective, resistant to wear and tear, less breathable. Nylon is Highly durable, lightweight, but less breathable and sensitive to UV radiation. Acrylic is a Synthetic alternative to wool, less breathable, and may pill. Spandex is Extremely elastic, used often for flexibility but not suitable as a primary material for backpacks.

The primary materials used in backpack fabrics are generally Nylon and Poly (Polyethylene). Occasionally, a blend of both is used. Both materials are derived from petroleum. Nylon is generally of higher quality and more expensive than Polyethylene. In terms of fabric feel, Nylon is softer.

Identification

Burn Test: One common method of identifying fibers is the burn test, where a small piece of the fabric is safely burned to observe the smell, flame, and residue.

Feel and Appearance: Often, fibers have a distinct feel and appearance—wool is more textured; cotton is soft, etc.

Fabric Technologies

Yarn Types

Spun Yarn: Made from staple fibers; usually softer but less strong

Filament Yarn: Made from continuous fibers; stronger and smoother

Fabric Structure

Woven: Interlacing two sets of yarns; can be plain, twill, or satin

Knitted: Interlocking loops of yarn; stretchier and more flexible

Non-woven: Fabrics made directly from fibers; less durable, used in disposable products

Subsequent Processes

Dyeing: Adding color

Coating: Adding layers for water-resistance or UV protection

Calendering: Enhancing the fabric's appearance and smoothness

Commonly Used Fabrics

Nylon

Advantages: It has high strength, high wear resistance, high chemical resistance, and good resistance to deformation and aging. Its downside is that it feels relatively hard to the touch. Notable brands include PERTEX and CORDURA.

Disadvantages: Sensitive to UV rays, may fade and deteriorate over time

Features: Often has a waterproof coating

Main Application: Everyday carry, travel backpacks, outdoor packs

Polyester

Advantages: Fade-resistant, chemical-resistant, relatively inexpensive. It offers good breathability and moisture-wicking properties. It also has strong resistance to acids, alkalis, and UV rays.

Disadvantages: Not as abrasion-resistant as nylon, lower tensile strength

Features: Generally water-resistant, but not as much as nylon

Main Application: School bags, casual daypacks

Cotton Canvas

Advantages: Natural, breathable, good aesthetic appeal

Disadvantages: Heavy, not water-resistant, prone to wear and tear

Features: Typically not water-resistant unless treated

Main Application: Casual backpacks, fashion-oriented packs

Leather

Advantages: Durable, high-quality feel, easy to maintain

Disadvantages: Heavy, expensive, needs regular upkeep

Features: Naturally water-resistant to some extent (but not suitable for prolonged exposure to water)

Main Application: Business backpacks, luxury packs

Spandex

ISPANDEX offers high elasticity and stretchability, as well as good recovery. Adding just 2% can improve the fabric’s mobility, draping, and shape retention. Its downside is weak resistance to alkalis, susceptibility to yellowing when exposed to chlorine or UV rays, and poor heat resistance. It's often blended with other materials. Some famous materials are LYCRA of DUPON (USA), "Dorlastan" of Bayer (Germany) and "Roica" of A.K (Asahi Kasei) (Japan).

Specific Fabric Types

Ripstop Nylon (R/S)

R/S stands for "Rip Stop." This fabric consists of small squares of nylon, woven with a thicker thread around the outer border and a finer thread in the center. Standard densities include 300D, 330D, 450D, and it can be used as a primary material in different sections of a backpack. The reverse side also has a coating.

Advantages: Extremely tear-resistant, lightweight

Disadvantages: Stiffer feel, less comfortable

Features: Usually excellent water and tear resistance

Main Application: Military backpacks, specialized outdoor packs

Oxford Nylon

A type of woven fabric, usually made of polyester or nylon, used for its strength and durability. The warp threads of Oxford fabric are typically composed of two strands of thread twisted together, and the weft also uses relatively coarse threads. Its weaving method is quite standard, often using 210D or 420D material, with a coating on the reverse side, commonly used as lining or partitions in bags.

PVC (Polyvinyl Chloride)

Advantages: Waterproof, chemical-resistant, versatile

Disadvantages: Less breathable, can feel plasticky

Features: Highly water-resistant

Main Application: Industrial backpacks, specialized waterproof packs

EVA (Ethylene-vinyl Acetate)

Advantages: Lightweight, shock absorbent, water-resistant

Disadvantages: Not as durable as some other materials, can degrade over time

Features: Often used in molded forms for structure

Main Application: Protective cases, children's backpacks

Kodra Nylon

Kodra is a fabric produced in Korea and can serve as an alternative to CORDURA to some extent. It's usually woven with Nylon and measures its strength by its fiber density, like 600D or 1000D. It also has a coating on the back and is comparable to CORDURA.

High-Density Nylon (HD)

HD stands for "High Density." The fabric visually resembles Oxford and is generally 210D or 420D. It is usually used as lining or partitions in bags, with a coating on the reverse side.

Dobby Nylon

The Dobby fabric seems to be made up of very tiny squares, but upon close inspection, you’ll see it's woven with two types of thread—coarse and fine—making it different on both sides. It is less durable than CORDURA and is usually only used in casual or short-trip travel bags. It rarely has a coating.

Velocity Nylon

Velocity is also a type of nylon fabric and is highly durable. It's generally used in mountaineering bags and also has a coating on the reverse side. It usually comes in 420D or higher densities. The fabric looks similar to Dobby.

Taffeta Nylon

Taffeta is a skinny fabric with multiple coatings, making it highly water-resistant. It is generally not used as the main material for backpacks but is suitable for raincoats or rain covers for bags.

Poly PU

This generally substitutes for Polyethylene and comes in varying densities from 150D to 1800D. A density of 600D can be used for the base of mountaineering bags. However, its weaving method is not as robust as CORDURA.

PU (Polyurethane): Often used as a coating for water resistance and added durability.

Air Mesh

Commonly referred to as "space net" in Chinese, Air Mesh is distinct from regular mesh. It has a gap between the mesh surface and the underlying fabric, usually around 3mm or more. This gap provides good ventilation and is generally used for straps or back panels of backpacks.

Each of these materials comes with its own set of advantages and disadvantages, and the choice often depends on the intended function of the backpack. For example, for an outdoor, rugged, heavy-duty backpack, KODRA or high-density nylon may be appropriate, while for a light, everyday backpack, oxford or regular nylon might suffice.

Some tips

Typically, when we buy a backpack, the fabric description in the manual is not very detailed, often indicating just "CORDURA" or "HD." These terms merely describe a type of weaving method. However, a more detailed description should include the material, fiber density, and weaving method. For example, "N. 1000D CORDURA" refers to 1000D nylon CORDURA fabric.

Misconception About 'D'

Many people assume that the "D" in woven materials stands for density, which is incorrect. "D" is an abbreviation for "denier," a unit of measurement for fibers. The calculation method for denier is as follows: a fiber 9,000 meters long that weighs 1 gram is considered 1 Denier. Consequently, the smaller the number preceding the "D," the finer and less dense the thread. For instance, a 210D fabric has very fine threads and is generally used as lining or partitioning, whereas a 900D or 1000D fabric has coarser threads, is more durable, and is commonly used for the base of the bag.

Conclusion

Different types of backpacks require different types of materials. When choosing fabrics, manufacturers should consider the intended use, durability requirements, and targeted price point of the product. Moreover, with advancements in technology, newer fabrics with advanced features like smart water-resistance and breathability are also entering the market, providing more choices and possibilities for the backpack industry.